Market volume of US$379 bn by 2025

New trends: fresh local foods, vegan, etc.

Failure rate between

70% and 80%

Food & Beverage industry challenges

As a Food and Beverage manufacturer, in addition to fierce competition, you face many challenges and constraints including regulations, labeling, non-compliance management, supplier relationship management, etc. Meeting these challenges plays a major role in the success of your products. It is therefore crucial to use appropriate solutions to ensure that you are in the successful 20-30%. New product development is essential to stay ahead of the competition, and you constantly need to innovate and speed up time-to-market, but you find that information is scattered all around your company. Properly managing communication and collaboration with your suppliers, and within your organization, is difficult owing to the large amount of information and data which is often disjointed or even missing entirely.

Aptean PLM Lascom Edition – Features

of Our Food and Beverage Software

Ease your new product development

- Organize your product development with workflows, stage-gate management, automated notifications, Gantt chart visualization, milestones, and reporting.

- Maintain a complete overview of your activities and make informed decisions assisted by features such as reports, timeline (i.e.: scheduling) and dashboards.

- Improve how you work with your suppliers: a secure portal provides centralized access and control of all relevant information, such as supplier data and documents, raw materials and packaging specifications, etc.

Speed up your R&D processes

and ensure compliance

- Quickly develop recipes with features including recipe yield and cost calculation, lists of ingredients and allergens, nutrition calculation, prototype management, and recipes/prototypes comparison.

- Comply with country-specific regulations on both recipe formulation and regulatory document management using features such as ingredient screening, to simplify product formulation and ensure the safety of your products.

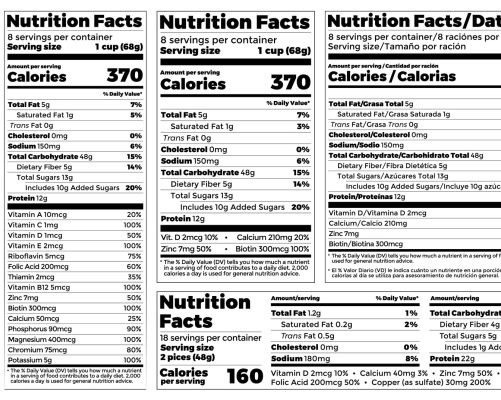

- Automatically generate nutritional fact panels: features specifically designed for label generation and management. Create FDA-USDA, European Regulation 1169/2011 compliant labels, ingredient statements, and a list of allergens.

- Create and manage your packaging specifications. You work from a specific marketing brief for the artwork to ensure that all requirements have been considered. Additional features, such as artwork proofing and comparison, optimize your entire graphics production process.

Ensure the quality of products

all along with their life cycles

- Analyze the impacts a change would have on your products: Consider and analyze the impact of any potential change (related to the formulation, regulation, packaging, costs, and so on) while providing complete traceability.

- Report, centralize, track and resolve customer complaints as soon as they arise. Add comments, digital photos, and any documents linked to incidents. Receive the right information at the right time thanks to automated workflows. Offer a suitable solution to customers, ultimately increasing their satisfaction.

- Trace and ensure the quality of all products throughout their life cycles, from suppliers to disposal: report, qualify, manage, and put an end to any non-conforming aspects before, during, or after production. This allows you to consolidate all the information necessary to analyze causes and plan remedial actions.

Aptean Food and Beverage PLM Lascom Edition

in video!

Feedback

Discover our 3 PLM offers tailored for Food and Beverages companies

Your food and beverage challenges,

our PLM features

New product

development

Foster product innovation, reduce time to market and achieve successful execution of the product.

Food and Beverage

formulation

The formulation step is essential, and it determines a products’ success or failure.

Packaging

management

Ensure your packaging’s aesthetic aspect and its compliance with regulations that are in force.

Food and Beverage

Regulatory Compliance

Follow current regulations and anticipate new ones.

Supplier Relationship

Management

Digitalize information and documents, and automate workflows and processes; hence improving the collaboration with your suppliers

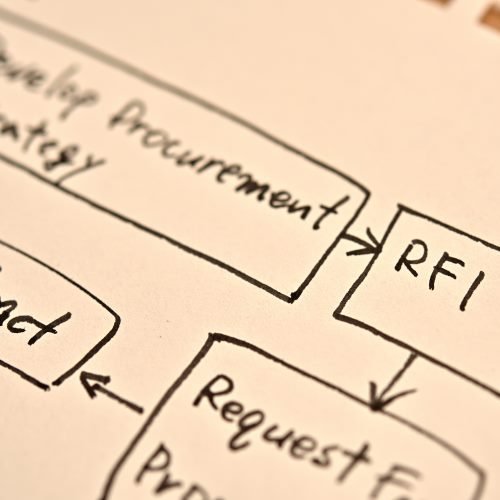

RFQ & RFP

Management

Request, check and analyze a large amount of information and data to make the best decisions.

Customer Complaint

Management

A second chance to improve customer loyalty by rectifying the problem.