“We don’t automatically receive the updated safety data sheets from our suppliers.”

“We work with very sensitive personal care products and safety data sheets are crucial to us.”

“We have to use homemade Excel connectors to keep our safety data sheets but we’re reaching a critical number of products and users.”

Safety Data Sheet (SDS) management is a major concern for cosmetic product development

Safety Data Sheets (SDSs) – formerly MSDSs or Material Safety Data Sheets – gather information on potential health hazards related to the exposure to chemical products or other potentially dangerous substances.

The Safety Data Sheet (SDS) specifies the composition of a chemical, identifies hazards, and recommends preventive and first-aid measures. It must be provided with the product upon delivery. For each hazardous chemical handled or used, employers must ensure that the SDSs are up-to-date and accessible to employees and downstream users.

The company is also accountable for the translation of those Safety Data Sheets in any required language to ensure a good understanding by all employees concerned. Thus, chemical manufacturers must provide the Safety Data Sheets of all raw materials linked to hazardous finished products.

Safety Data Sheet management involves a significant number of information and data that need to be identified, gathered, organized, tracked, and updated, which also relies on various stakeholders, both internal and external. If a business fails to provide, at any time, the required SDSs in compliance with the REACH regulation in Europe, or regulations set by the Occupational Safety and Health Administration (OSHA) in the United States of America, it can face important financial impacts: product withdrawal, fines, legal procedures, etc.

Without an efficient data and document management solution, meeting SDSs requirements becomes a dangerous challenging.

Aptean PLM Lascom Edition: your SDS management software

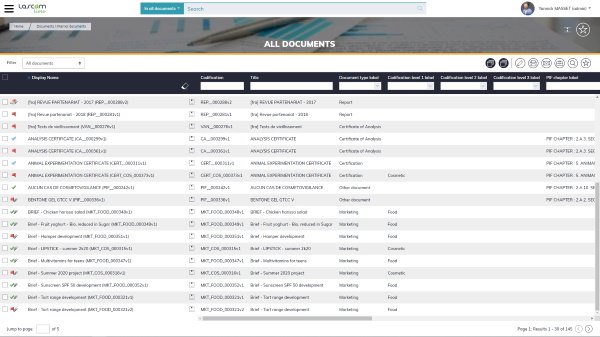

Thanks to its Electronic Data Management System (EDMS) capacities, Aptean PLM Lascom Edition software enables businesses to dematerialize, gather, store, track and update their safety data sheets in compliance with regulations in force. Creation, versioning, and lifecycle management of SDSs are guaranteed. Setting up customized workflows facilitate the editing, follow up and update of the characteristics and chapters of your SDSs.

On another hand, the supplier portal also speeds up and secures collaboration around SDSs with suppliers and external partners. Manufacturers using chemicals can retrieve the SDSs directly from their suppliers and store them in Aptean PLM Lascom Edition repository. Therefore, a finished product will be directly associated to the SDSs of all raw materials it contains in order to easily retrieve them. On the supplier’s side, the information can be dematerialized and the SDSs can be generated using data from the repository to enforce reliability.

The alert system of our Safety Data Sheet management software automatically notifies managers when a raw material or finished product does not compile all necessary SDSs, or when an update is required.

Our PLM offer for the cosmetic and personal care industry