“Our non-conformity management software has limited capacities of attachment management.”

“We want to set up a quality standard across our brands and need to provide them with a tool they can all use.”

“Our reaction and correction plans are complex and associates sometimes miss critical steps.”

The slightest non-conformity can ruin months of hard product development work

A non-conformity is any discrepancy between the delivered design or product and the contractual requirements of a client’s order (e.g. specifications, contracts, plans, etc.) or the requirements of the company (e.g. processes, memorandums, instructions, manufacturing plans, sub-orders). If not properly handled, a non-conformity can have serious consequences, especially on costs associated to re-formulation, decrease of customers’ satisfaction, and loss of certification, to name a few.

Non-conformity management is essential to control and certify the quality of any product. Quickly identifying non-conformities and putting in place the necessary corrective and preventive measures plays a key role in optimizing the quality of developed products.

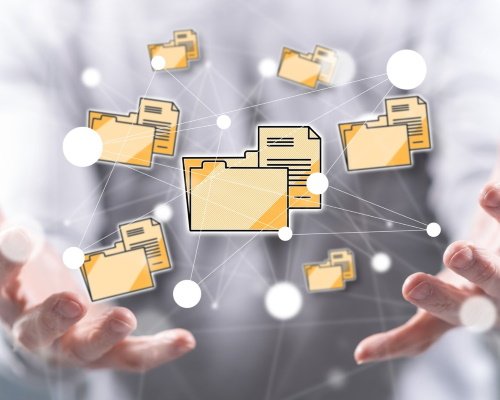

An effective solution to manage these non-conformities is the implementation of a non-conformity management software. Such software allows businesses to report an incident regarding a product, dematerialize and gather non-conformity information, set up an action plan, and efficiently track any data or document related to the event.

A dedicated solution should also enable your business to build up and consolidate collaborative processes to identify, qualify, register, correct and analyze any non-conformities either:

- Internally – during the design, preparation, manufacturing and assembly steps, and audit activities.

- Externally – when the clients receive the product, during the product’s use or after its use.

How to digitally manage non-conformities

Lascom from Aptean offers a non-conformity management tool enabling users to report any incident regarding a product. With this tool, it is easy to add comments, digital photos, documents, and other format of information related to the incident. The person responsible for the management of these events is then assigned to the assessment of this non-conformity to identify its causes and set up the appropriate corrective plan. It ensures a suitable solution is quickly operated to mitigate any potential inconvenience cause to a client, for instance.

The non-conformity management module relies on two key elements of Aptean PLM Lascom Edition.

The first one is the knowledge database. Having a common knowledge base allows non-conformities’ information to be dematerialized/digitalized. Then, this data can easily be consolidated through indicators.

The second element is the workflow engine. Dynamic processes and workflows guarantee that the right people receive the right information at the right time.

The complete and accessible non-conformity management solution

Aptean PLM Lascom Edition is an out-of-the-box Product Lifecycle Management (PLM) software integrating holistic marketing, quality, and regulatory compliance management modules. Our modulable solution enables Consumer Packaged Goods (CPG) manufacturers to quickly and adequately prevent and react to non-conformity events.

- Internal and external process – Manage both, the test results on an item/article/product (internal) and the customers’ complaints (external)

- Declare a non-conformity – Easily capture information following templates (e.g. description, product concerned, etc.), associate any document related to non-compliance (e.g. photos, comments, etc.), and select which process to follow.

- Qualify the non-conformity – The person in charge of the non-conformities’ qualification automatically receives a notification to consult the information and input his/her results and comments.

- Close the non-conformity – Input information on how the non-conformity has been solved. Once it is closed, every non-conformity is saved in the database, enabling latter quick search based on keywords, customers, products, types of non-conformities, etc.

Our PLM offer for Food & Beverage product manufacturers!